Air Velocity Monitoring for Critical Containment

Airflow is Essential for Critical Containment

Engineering controls are used to protect laboratory workers. Examples include exposure control devices (ECDs) such as chemical fume hoods and biosafety cabinets (BSCs), which are ventilated to contain harmful toxins and odors, and safeguard against fume releases into the room. These critical containment cabinets differ in design, and airflow requirements vary as well, according to the application.

Rooster™ Monitor Retrofits Protect Laboratory Personnel

Several microelectronics and semiconductor testing laboratories have upgraded engineering controls by retrofitting Rooster™ Monitors to wet process stations and eliminating legacy magnehelic gauges. One such retrofit involved vertical laminar flow workstations, which are being used for trace metal analysis and materials research. The hoods are kept at a negative pressure with inward airflow at the front, to prevent contaminants from escaping, and supply air is HEPA filtered to protect product. All cabinet air and fumes are exhausted to the outside.

The Rooster™ visually and audibly alarms if the speed of the exhaust flow drops below a predefined set point, and if the downflow air velocity drops below its predefined set point. A sidewall sensor measures air velocity in the exhaust duct, acting as a flow through device and pulling in clean laboratory air, and an F-Series probe-style sensor measures downflow velocity after HEPA filtration. Information from a connected sash position sensor is used by Rooster™ to determine volume flow of the fume hood, and exhaust flow, downflow, and volume flow are displayed simultaneously. The Rooster™ Monitor also provides switching for auxiliary equipment such as a light or fan, and its configurable timer notifies personnel when it’s time to replace HEPA filters.

Note: ANSI/ASHRAE Standard 110 and EN 14175-3 specify methods for laboratory testing of fume hoods.

Contact Degree Controls for airflow management solutions for your critical containment applications, and please take good care.

DEMONSTRATION VIDEO: Rooster™ Monitor

Airflow Monitors

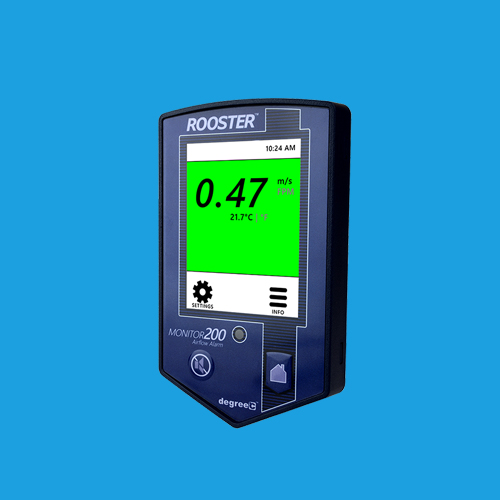

Rooster™ Monitor200

The Rooster™ Monitor200 with BACnet® MS/TP capability for a wide range of critical containment applications where airflow is to be monitored, alarmed, and communicated to building management systems (BMS). Sophisticated controls include sash position sensing, programmable relay outputs mapped to custom hardware, and PI motor control output.

Rooster™ Monitor100

The Rooster™ Monitor100 is an airflow monitoring and alarm system for critical containment applications, including chemical fume hoods, biological safety cabinets, laminar flow hoods and other applications where airflow is required to be viewed, monitored, alarmed, logged and communicated to building and laboratory systems.

Rooster™ Pressure100

The Rooster™ Pressure100 is a next-generation air pressure, temperature and humidity monitor with a user-friendly touchscreen interface for configuring alarm set points and output behavior. The Rooster™ Pressure100 is designed to meet the monitoring guidelines for USP 797 & USP 800, as well as FDA guidelines for 503a/503b compounding pharmacies.

John Callanan

As a Technical Sales Engineer John works with clients to provide airflow monitoring solutions tailored to their needs. He holds a Bachelor of Science Degree in Technical Management.