Sidewall Air Velocity Sensing for Critical Containment and Industrial Applications

Performance & Reliability with Sidewall Air Velocity Sensing

Lab managers often choose to use sidewall sensors to maintain the face velocity of fume hoods and biosafety cabinets, instead of duct-mounted probe-style sensors, in applications where the exhaust flow is dirty or extremely hot. The long term exposure of probe-style sensors to depositing particulates or corrosive chemicals may compromise sensor accuracy as well as reliability. The sidewall or side flow sensor overcomes these issues by acting as a flow-through velocity device, drawing in clean, ambient air, rather than contaminated exhaust air, to measure airflow. Sidewall sensors are typically mounted to the side of critical containment cabinets.

Sidewall sensing technology is well suited for chemical fume hoods, exhausted laminar flow stations, and industrial applications including:

- Measurement of airflow into curing ovens for disk drive plating applications

- Optimization of airflow intake valves in combustion chambers

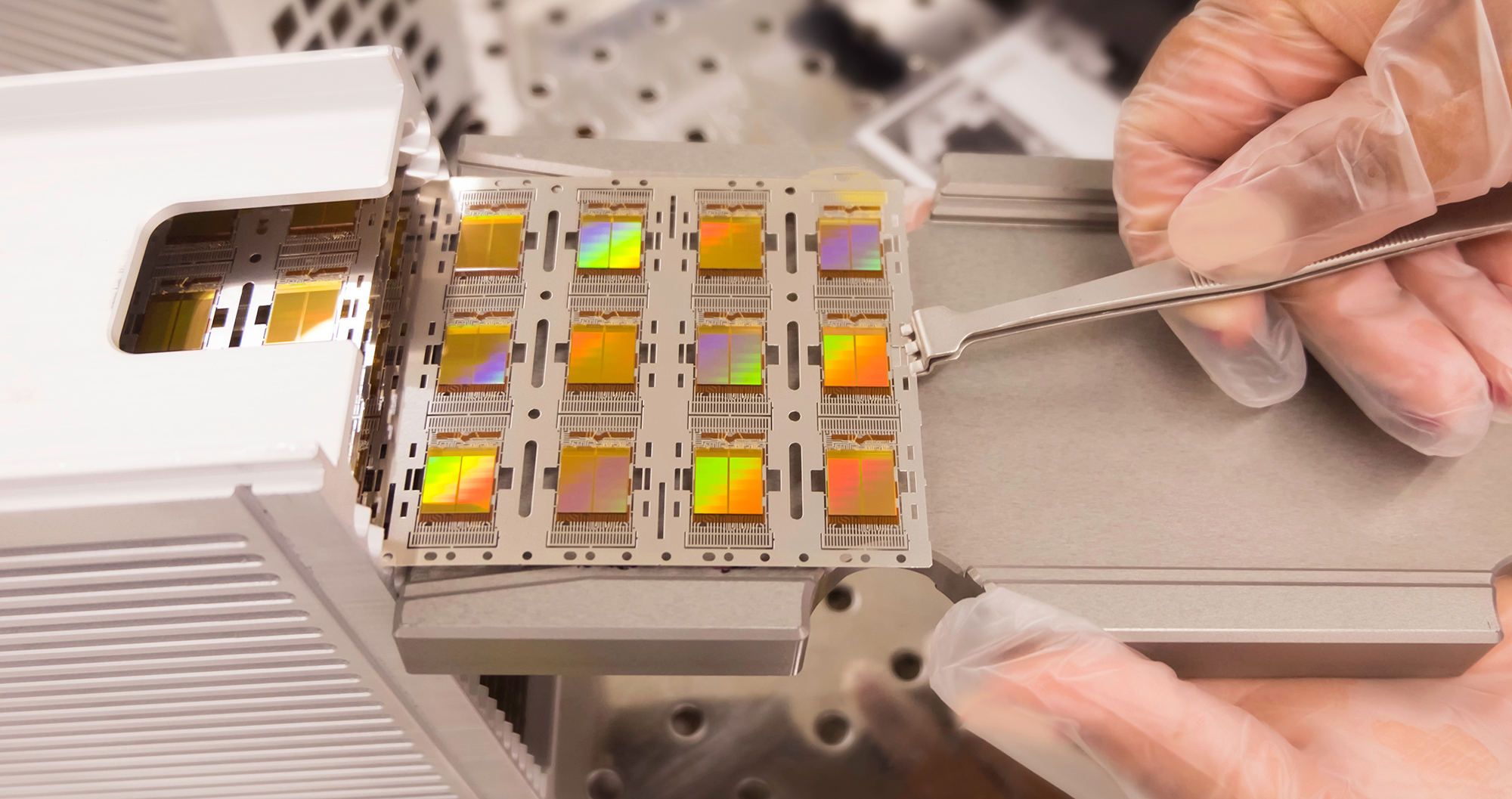

- Evaporative processes in semiconductor wafer fabrication

Sidewall Sensing for Negative Pressure Laboratory Cabinets and Fume Hoods

The actual velocity measured through a side-wall sensor is a function of the cabinet’s negative pressure, which is created by the airflow exhaust system. The negative pressure changes when a sash is opened, the overhead exhaust system adjusts its speed, or there is a change in room pressure, and this manifests itself as a pressure change, measured by the side-wall sensor as a velocity change. The measured air velocity of the side-wall sensor exhibits excellent correlation to these changes in pressure, and their corresponding effect on face velocity.

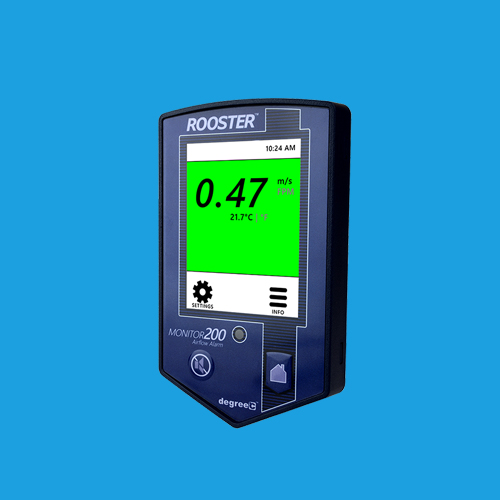

Use the side-wall sensor with the Rooster™ Alarm or Rooster™ Monitor to monitor face velocity. Follow the calibration procedure, measure air velocity entering the hood, and communicate any changes in airflow to the fume hood controller to adjust and maintain the critical face velocity set point for safe and efficient fume hood containment. A closed loop sidewall sensing control system can also be used in conjunction with sash position sensing control.

Contact Degree Controls to learn about sidewall sensing for airflow alarms & monitors and remote head sidewall sensors where the sensor element is built remotely from the sensor electronics.

DEMONSTRATION VIDEO: Rooster™ Monitor

Airflow Monitors

Rooster™ Monitor200

The Rooster™ Monitor200 with BACnet® MS/TP capability for a wide range of critical containment applications where airflow is to be monitored, alarmed, and communicated to building management systems (BMS). Sophisticated controls include sash position sensing, programmable relay outputs mapped to custom hardware, and PI motor control output.

Rooster™ Monitor100

The Rooster™ Monitor100 is an airflow monitoring and alarm system for critical containment applications, including chemical fume hoods, biological safety cabinets, laminar flow hoods and other applications where airflow is required to be viewed, monitored, alarmed, logged and communicated to building and laboratory systems.

Rooster™ Pressure100

The Rooster™ Pressure100 is a next-generation air pressure, temperature and humidity monitor with a user-friendly touchscreen interface for configuring alarm set points and output behavior. The Rooster™ Pressure100 is designed to meet the monitoring guidelines for USP 797 & USP 800, as well as FDA guidelines for 503a/503b compounding pharmacies.

John Callanan

As a Technical Sales Engineer John works with clients to provide airflow monitoring solutions tailored to their needs. He holds a Bachelor of Science Degree in Technical Management.