USP 800 Compliance for Compounding Pharmacies & Labratories

USP 800 Compliance for Compounding Hazardous Drugs

If you’re reading this now, chances are you’re doing so with a bit of anxiety … and your anxiety is justified by the December 1, 2019 deadline for United States Pharmacopeia (USP) Chapter <800>. You’re not alone. Other compounding facilities are in a rush to make physical and policy changes to ensure that they comply with USP 800 and can stay in business. The good news is that we can help.

Understanding USP 800

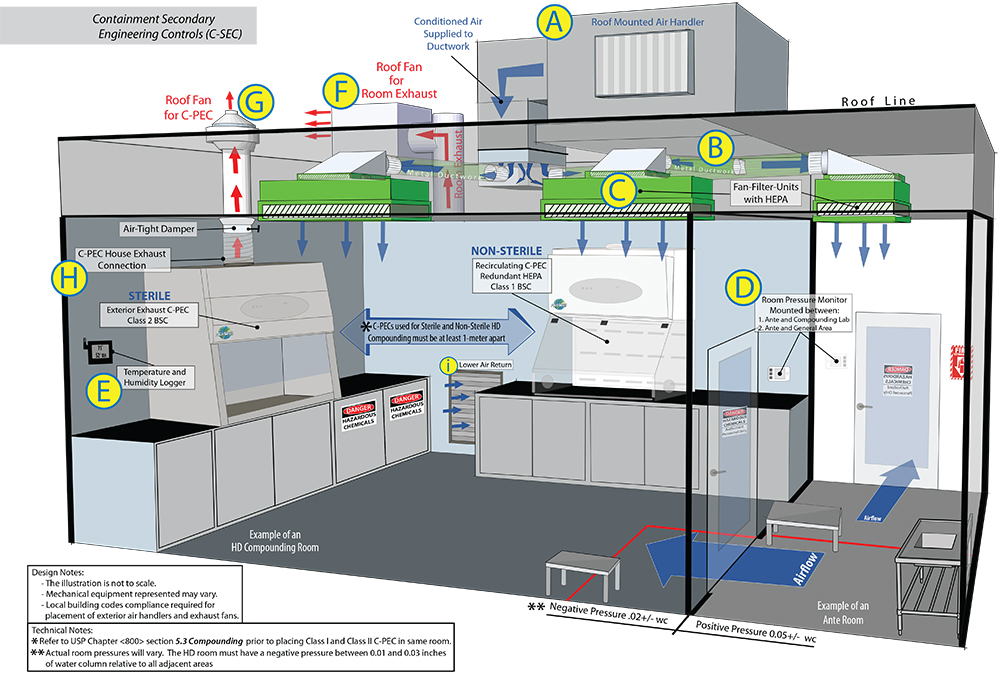

USP 800 details the regulations for handling of hazardous drugs. This could be in compounding pharmacies, hospital pharmacies, and medical centers. USP 800 augments USP 797, and the mandates are intended to provide additional protection to pharmacists and workers to ensure safe handling of chemotherapy and other hazardous drugs. But the requirements extend beyond the act of physically handling these drugs and extend to the design of the facility itself, as well as the engineering controls for the facility.

Photo Credit: LabRepCo

Major Difference between USP 797 and USP 800?

The biggest difference between USP 797 and USP 800 that impacts the compliance strategies of a facility, pertains to the Segregated Compounding Area (SCA). USP 797 only allows low-risk level nonhazardous and radiopharmaceutical Compounded Sterile Preparations (CSPs) with 12 hour or less beyond-use date (BUD) to be prepared in an unclassified segregated compounding area.

USP 800 allows low and medium risk level hazardous drug CSPs to be prepared in an unclassified containment segregated compounding area (C-SCA). The C-SCA is required to have fixed walls, be externally vented with 12 air changes per hour (ACPH) and have a negative pressure between 0.01 and 0.03 inches of water column relative to the adjacent areas.

Monitoring Negative Pressure for USP 800 Compliance

Establishing negative pressure is one thing, but some facilities struggle with managing it. This is where our product, Rooster™ Pressure100, comes in. The Rooster™ Pressure100 monitors, pressure at the room level and signals with an alarm if pressure falls outside the set threshold. This helps bring your facility into compliance. In addition to air pressure and pressure mode, the Pressure100 monitors and displays temperature and relative humidity.

Pressure100 is easy to use and set-up with easy integration into your system or facility. An intuitive interface guides the operator through procedures with on-screen instructions. Users can access data logging, as well as add laboratory specific information, such as room name, phone numbers, and unique asset tags via the built-in USB port. Single and multiple event alarms are clearly displayed to the user, and the INFO button allows instant access to calibration date, alarm thresholds and other critical system information. The Pressure100 conveys status, such as pressure rises and drops, by updating the color of the background screen, and critical safety alarms are augmented with a blinking LED. Password protection allows users to personalize operational experience, but not override safety features set by facility managers.

Get USP 800 Compliant Now!

Call 1.877.334.7332

Rooster™ Airflow Alarm

Designed as a simple retrofit option for fume hoods and biosafety cabinets, The Rooster™ is a fast, reliable, and affordable way to monitor airflow safety and achieve OSHA or NSF-49/ANSI compliance.

Rooster™ Monitor100

The Rooster™ Monitor100 is the next-generation airflow monitoring and alarm system for critical containment applications, including chemical fume hoods, biosafety cabinets, & laminar flow hoods

More Information on USP 800 Compliance:

United States Pharmacopeia - USP 800

About Degree Controls, Inc. - DegreeC

DegreeC engineers and manufactures airflow solutions delivering both instrumentation-class airflow sensors and sensors embedded in the world's most demanding products. Our airflow monitoring solutions for laboratories, buildings, and industrial safety applications bring air precisely where it's needed.

Steve Carter

Is a published author who has contributed editorial content to a wide range of technical publications. He handles marketing operations for DegreeC including

social media, Blogs, and online content.