The Role of Ventilation and Airflow in Mitigating Endemic Disease

The Role of Ventilation and Airflow in Mitigating Endemic Disease

We know that all respiratory infections, starting with influenza and including the four endemic human coronaviruses, spread more virulently during winter months when people are indoors and closer together. In keeping with this understanding, SARS-CoV-2 has been transmitted more frequently in the Northern Hemisphere because colder weather forces the masses indoors more often and for longer periods of time.

It is also clear that inadequate indoor ventilation exacerbates and perpetuates the transmission of respiratory infections. Specifically, since SARS-CoV-2 is spread by airborne viral particles, the concentration of those particles cannot be diluted or dispersed by natural wind as they are when people are outdoors. This fact and the reality that SARS-CoV-2 may become endemic, and something that we must live with much like we do with seasonal flu, has HVAC engineers examining the design of HVAC systems, air changes per hour, improved filtration, and air velocity within HVAC systems. As resources, the CDC has posted guidelines for Ventilation in Buildings and ASRAE has published Ventilation for Acceptable Indoor Air Quality.

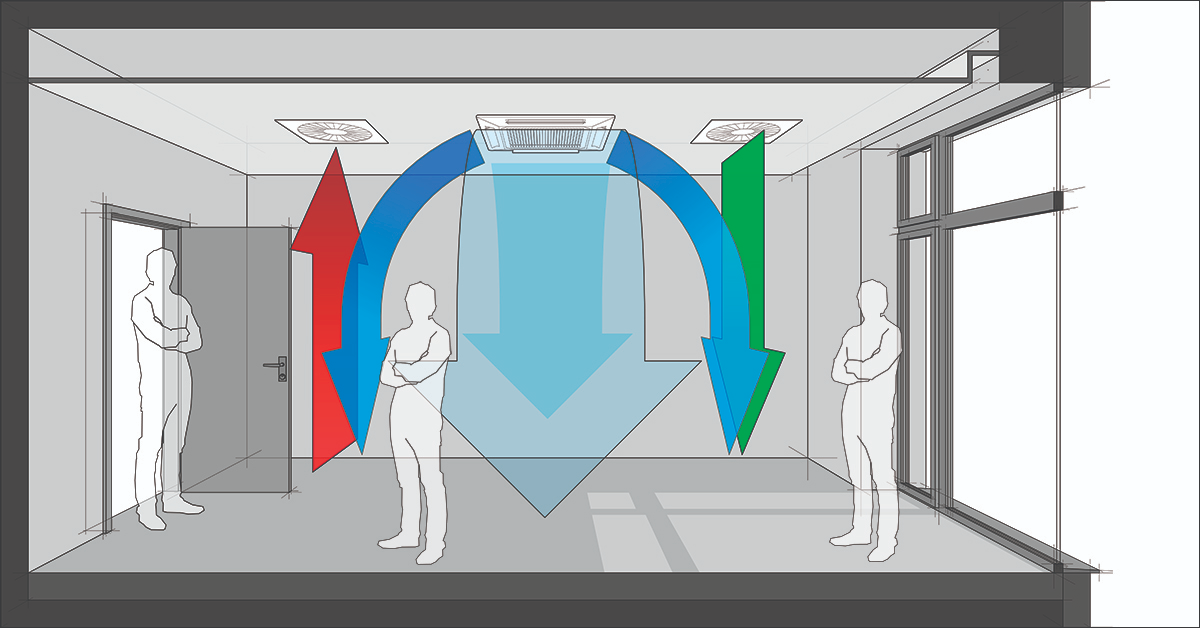

In this Blog, we’ll address indoor ventilation and the airflow required to produce and maintain the safety of indoor air. This examination will include industry best practices, as well as some of the instrumentation for measurement and monitoring that is required to achieve those best practices. Starting with ventilation, the CDC recommends increasing the ventilation rates indoors as a means of reducing the concentration of airborne pathogens such as SARS-CoV-2. A logical start is to clean and inspect your current ventilation system and, in the process, open diffusers and adjust dampers. You can also add hardware like an air-side economizer to bring outdoor air inside and to distribute that air more efficiently. For buildings without ventilation systems, you can increase natural ventilation by opening windows and it is recommended that the average number of indoor occupants be decreased during a pandemic.

Ventilation Required to Mitigate Endemic Disease

It is important to measure outdoor air intake by monitoring air change rates for spaces in your building. This helps to reduce the concentration of airborne viruses and minimize the spread infectious diseases. Air changes per hour (ACH) is the volume of air that an HVAC system can deliver in an hour divided by the room volume. For calculations, CFM is converted to CFH and then divided by the volume of the room to derive ACH. To determine air changes per hour for a space, measure air velocity using a probe style air velocity and temperature sensor mounted in-duct, and then use the air changes formula.

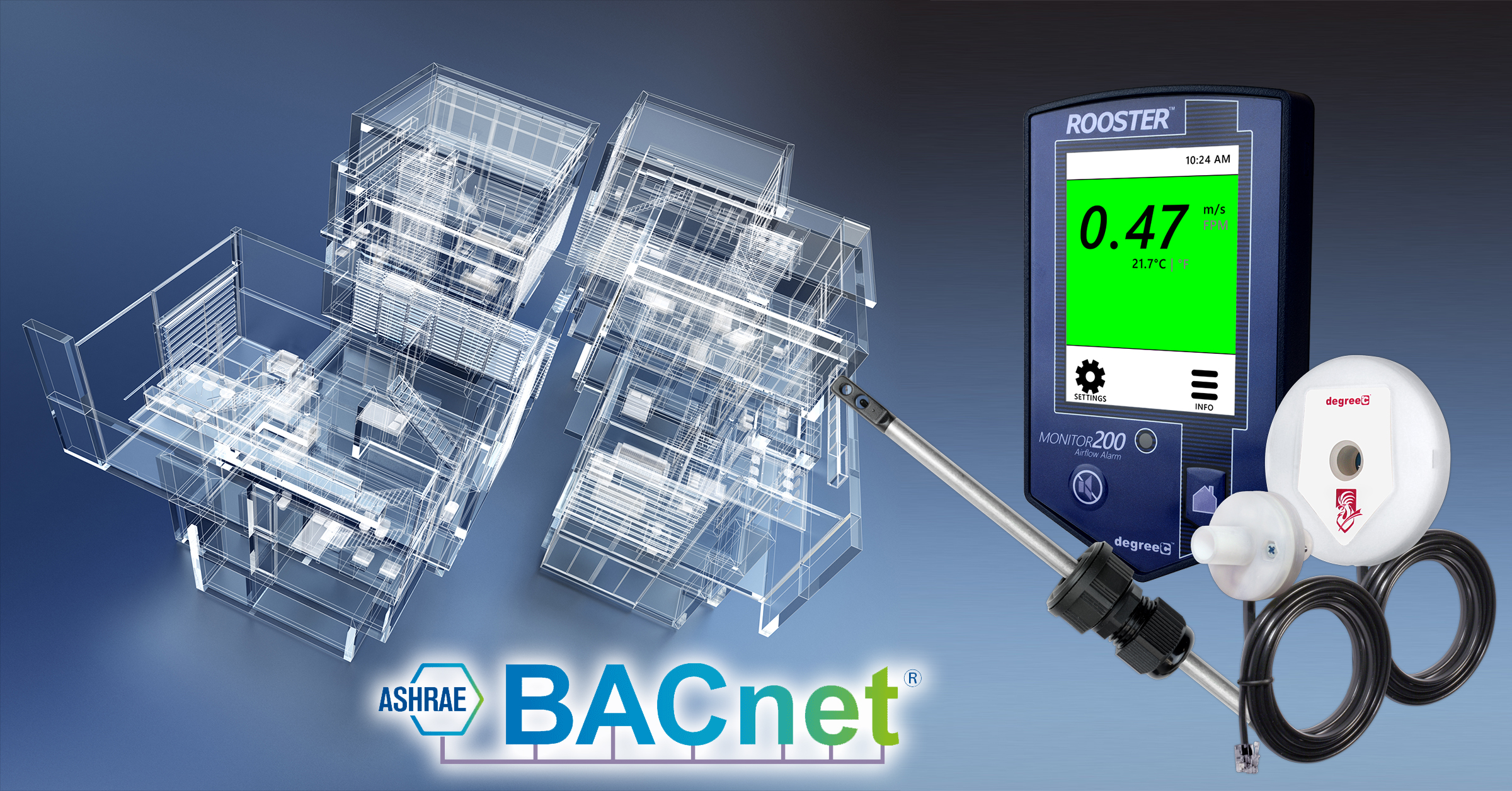

As an alternative to manual mathematics, you can install an airflow monitor (with a duct-mounted air velocity sensor) that displays air changes per hour (ACH). The Rooster™ Monitor200 with BACnet® MS/TP capability can transmit real-time data to your controller or Building Automation System (BMS) and can yield reduced energy costs and maximum building efficiency.

HEPA Filters and Endemic Disease

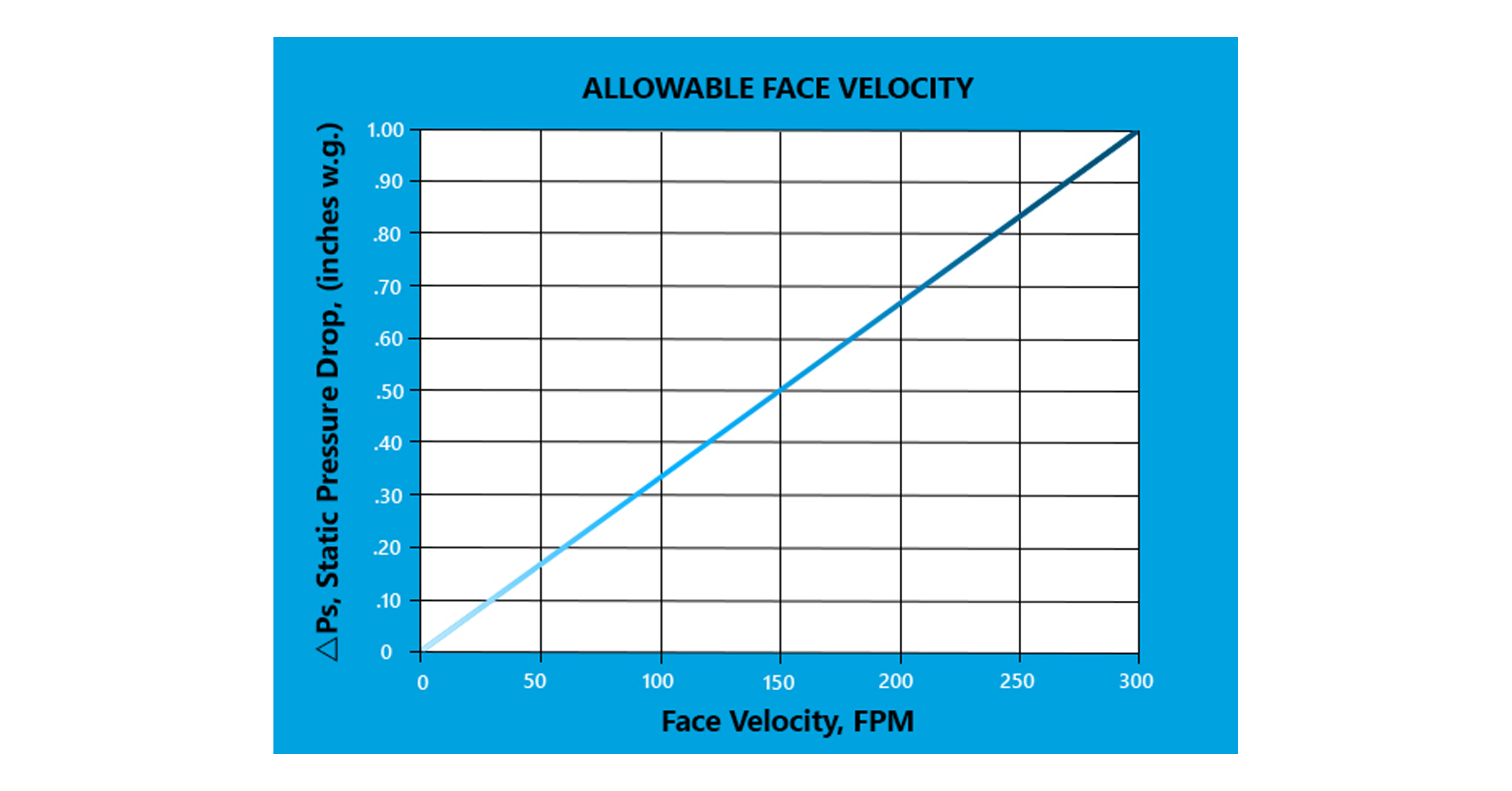

With the CDC’s call for “increased airflow”, HEPA filters within HVAC systems may end up being used beyond their capacity. It is extremely important for HVAC technicians and building managers to have a firm understanding of the filters they are using, as well as the specifications for those filters. HEPA filters must be used at their rated pressure drop and with an airflow face velocity that does not exceed the manufacturer’s specifications. The diagram below illustrates this interplay between pressure drop and face velocity and there is more detail on this specific aspect HERE.

The illustration above shows an F400 Air Velocity & Temperature Sensor in front of the HEPA filter and a user-adjustable S100 Probe Style Switch after the HEPA filter. The F400 sensor can be installed from outside the duct using a gland fitting and requiring a single hole in the duct. The S100 is installed using a clamp and also requires a single hole in the duct. In the case of the S100 switch, when air velocity drops below the user-defined trip point, the S100 signals for low flow with your choice of Normally Closed (N.C.) or Normally Open (N.O.) relay output and on-board LED indicator. The air velocity trip point is set by the user via potentiometer adjustment with the S100 is installed in its application environment. S100 installation is fast and easy with included mounting bracket options and convenient push-wire connections.

Aside from filtration systems, measurement of air velocity throughout the HVAC system helps to verify its optimal operation and periodic quantitative airflow tests should be performed. Since the accuracy of volumetric airflow measurement depends on the location of the measurement, we suggest following ASHRAE guidelines. This includes placement of the air velocity sensor 7.5 duct diameters downstream and 3 duct diameters upstream from any obstructions or changes in airflow direction, and away from junctions or fans that may create turbulence which can impede accurate measurement. Measurement accuracy can be improved by placing air velocity sensors in multiple locations within a plane. ASHRAE provides guidance on the number and location of measuring points within a plane for both rectangular and circular ducts. A minimum of 25 points is specified for rectangular or square ducts, and a minimum of 18 points is specified for circular ducts.

While all of this is certainly a lot to accomplish, the changes that you make in your HVAC system with the intention of reducing the spread of infectious disease and improving the safety of your facility, will likely have the byproduct of increased efficiency and lower overall costs. Therefore, once you’ve implemented these changes, you should also verify that your system is free of leaks that may sacrifice some of the efficiency. This can be done with airflow visualization products that make the ambient pattern of air visible. These foggers can also be used to validate the performance of intakes and to identify any areas of turbulence in your spaces that may jeopardize the full effectiveness of your efforts to improve the safety of your facility.

Degree Controls, Inc. manufactures sensors and instruments mentioned above, and all of them can be ordered online. We also offer world-class consultation and support so that you can be sure to get exactly what you need for your facility. We join with you in the effort to mitigate the impact of endemic disease and are happy to help you to create safer spaces through improved airflow and ventilation.

DEMONSTRATION VIDEO: Rooster™ Monitor

Steve Carter

Is a published author who has contributed editorial content to a wide range of technical publications. He handles marketing operations for DegreeC including social media, Blogs, and online content.