Monitor Room Pressure for Safe Environment of Care

Monitor Room Pressure for Safe Environment of Care

Hospitals and health care facilities recognize the importance of protecting patients, workers, and patrons from hazards. They evaluate their ventilation systems on an ongoing basis, and work continuously to make systems and engineering controls better for improved health and safety.

Healthcare organizations are installing room-based pressure monitors in all types of functional areas to further strategies for infection control and ensure their pressurization process is compliant. Reference ANSI/ASHRAE/ASHE Standard 170-2017, Ventilation of Health Care Facilities, for ventilation recommendations for spaces directly affecting patient care. Table 7.1 shows what the pressure relationship to adjacent areas should be for spaces within health care facilities.

Know the Pressurization Level for Your Space

Use a Rooster™ Pressure100 from Degree Controls to continuously measure and monitor positive or negative pressure differentials, to maintain proper pressurization for functional spaces. The Pressure100 is efficient, easy to use, and air pressure trip points can be set by the user via color touch screen display. The Pressure100:

- Alarms audibly and visually when pressure is at an unsafe level, and can be easily integrated into laboratory or building management systems.

- Continually displays actual air pressure measurements, as well as air temperature and relative humidity.

- Links pressure data to functional area with customizable room names.

- Features data logging with convenient USB export for compliance record keeping, demonstrating that required levels have been achieved.

See our website for additional benefits and Rooster™ Pressure100 information.

Outdated Instruments Don’t Show Actual Pressure

Upgrade outdated ball in tube devices. Know what pressure differentials are, alert staff when user set thresholds are exceeded, and store data to identify problems early. Proper pressurization of space is critical to safety, and continuous monitoring of pressure levels is just as important. When actual pressure differentials are available, rather than just the existence of “some differential”, a higher level of safety can be achieved. Contamination may still occur if pressure differentials are too small.

Contact Degree Controls to purchase your Rooster™ Pressure100 today, maintain proper pressurization levels, support infection control, and meet compliance standards. Even facilities with limited budgets are taking steps to implement facility-wide pressure monitoring. They’re first introducing room pressure controllers to areas most in need, and then using a phased approach to expand deployment.

Our sincere thanks to all in the healthcare community.

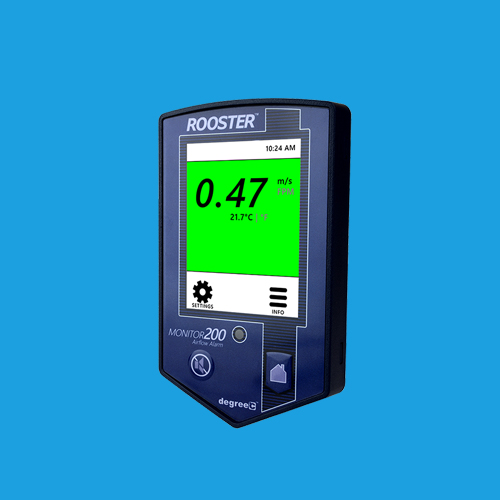

Rooster™ Monitor200

The Rooster™ Monitor200 with BACnet® MS/TP capability for a wide range of critical containment applications where airflow is to be monitored, alarmed, and communicated to building management systems (BMS). Sophisticated controls include sash position sensing, programmable relay outputs mapped to custom hardware, and PI motor control output.

Rooster™ Monitor100

The Rooster™ Monitor100 is an airflow monitoring and alarm system for critical containment applications, including chemical fume hoods, biological safety cabinets, laminar flow hoods and other applications where airflow is required to be viewed, monitored, alarmed, logged and communicated to building and laboratory systems.

Rooster™ Pressure100

The Rooster™ Pressure100 is a next-generation air pressure, temperature and humidity monitor with a user-friendly touchscreen interface for configuring alarm set points and output behavior. The Rooster™ Pressure100 is designed to meet the monitoring guidelines for USP 797 & USP 800, as well as FDA guidelines for 503a/503b compounding pharmacies.

John Callanan

As a Technical Sales Engineer John works with clients to provide airflow monitoring solutions tailored to their needs. He holds a Bachelor of Science Degree in Technical Management.