Airflow Sensor is Key Element of HVAC Control System

Airflow Sensor is Key Element of HVAC Control System

HVAC Series "Analyzing Airflow" Part 4:

Note: Part 3 of our HVAC Series – Analyzing Airflow - Configurable Air Velocity Sensing & Controls for Duct Airflow Measurement discusses available configuration options from Degree Controls and describes our embedded platform solution for a large duct application.

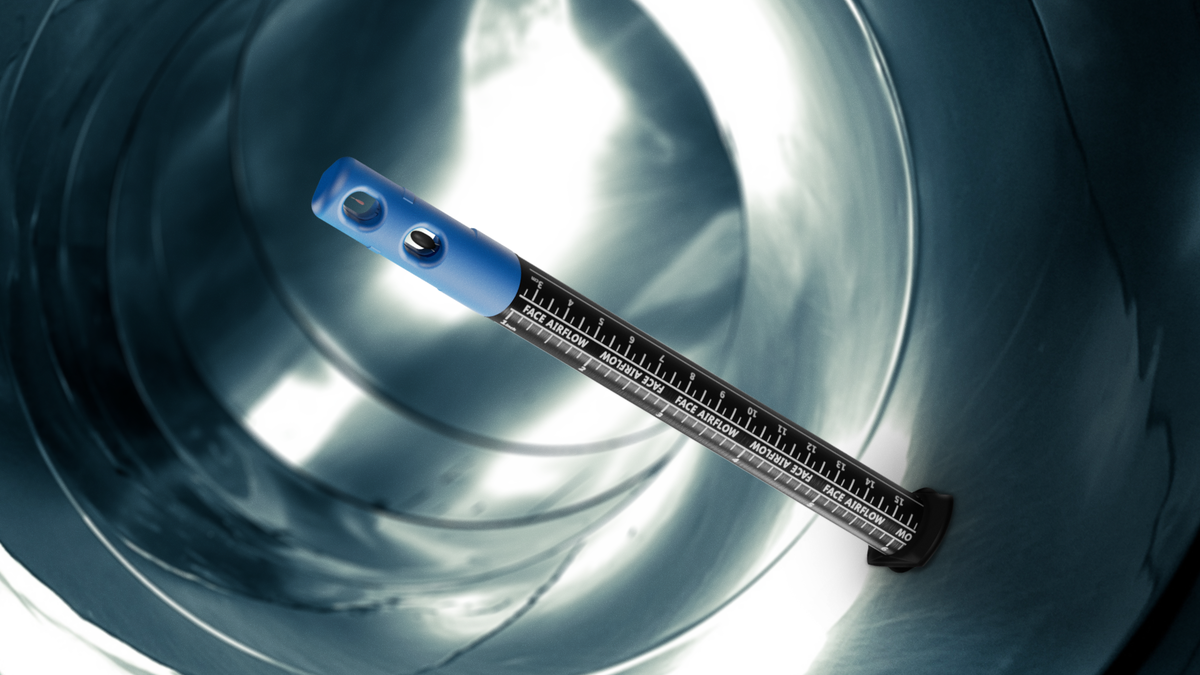

A well-run HVAC control system is conducive to a healthy and comfortable indoor environment, helps maintain equipment life expectancy, and helps save costs. The control system is only as good as its sensing devices. Degree Controls airflow sensors are key elements of HVAC control systems.

Care should be taken in choosing the right airflow sensor for your application. Close attention should be paid to both sensor mounting and location to ensure that it will function according to published specifications. Here are some sensor considerations to evaluate:

- Check the specs against the environment the sensor will be used in.

- Consider outside influences such as vibration, spray water or debris. Decide if any special provisions will be needed for protection.

- Determine where the sensor will be mounted. Avoid mounting the sensor in turbulent locations caused by elbows or duct size changes, and follow ASHRAE best practices.

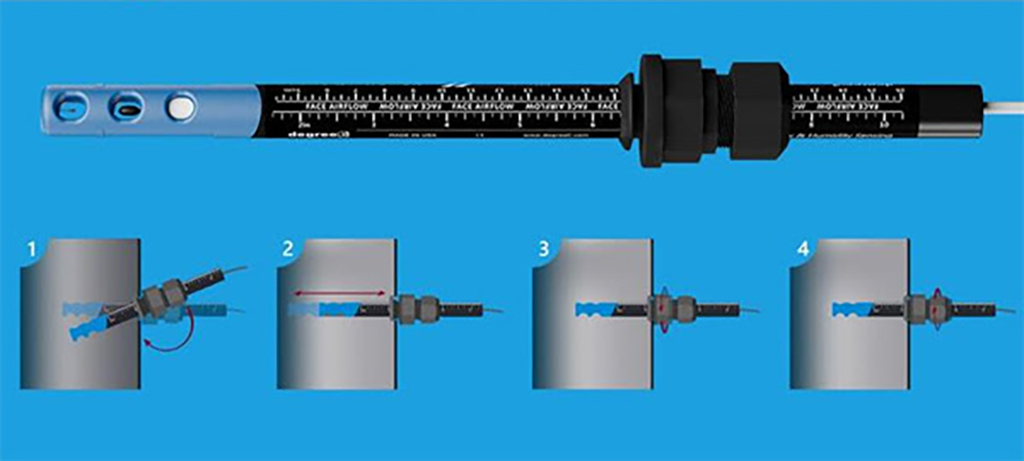

- Determine the insertion depth needed for the application. The main airflow cavity surrounding the flow thermistor should be in the center of the duct when the sensor is installed.

- Be mindful of the size of the airflow probe. A probe may impact flow and thus airflow measurements in a small cross-sectional duct. An airflow sensor with remote head or low profile head may be needed.

- Find out what airflow velocities the sensor is expected to encounter. Choose the sensor velocity range accordingly.

- Understand the sensor flow direction and whether it is non-directional or bidirectional. The main airflow cavity surrounding the flow thermistor must be orientated perpendicular to airflow being monitored in order for it to function as designed.

- Mount the sensor securely. Do not overtighten °C-Clamps.

- Dress the sensor cable. Allow a sufficient cable bend radius and loop to prevent stress and premature wear. The wiring system should allow for serviceability.

- Maintain sensor signal integrity. Avoid excessive cable length, and keep cabling separate from high voltage lines.